- ※ Gear coupling

- ※ Diaphragm coupling

- ※ Plum blossom coupling

- ※ Star flexible coupling

- ※ Elastic pin coupling

- ※ Elastic pin gear coupling

- ※ Elastic sleeve pin coupling

- ※ Slider coupling

- ※ Rigid coupling

- ※ Sprocket chain coupling

- ※ Tyre coupling

- ※ Serpentine spring coupling

- ※ Universal coupling

- ※ Bracket series

- ※ Stirrer series

- ■ There are tips for surveying and mapping to make couplings...

- ■ Explain the movement of the diaphragm coupling...

- ■ Crusher coupling and pump coupling...

- ■ XINLAN manufacturers explain the coupling...

- ■ Durable gear coupling 38 Luo...

- ■ GSL type product XINLAN mechanical gear...

- ■ Improve the ranking of the coupling website...

- ■ Couplings with bolts XINLAN...

Open up and innovate, customer first

- ■ At the end of 2020, steel and freight are...

- ■ Find the coupling manufacturer to report...

- ■ XINLAN Machinery will chat with you about snakes...

- ■ Hundred sets of plum blossom 4 type coupling...

- ■ LZ type elastic coupling 2016...

- ■ 45# Steel Coupling/40 Luo Steel...

- ■ The nationwide increase in freight rates directly affects...

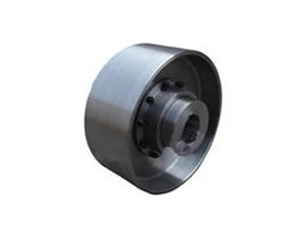

The WGP type with brake discDrum shapeGear couplingIt includes a left shaft sleeve and a right shaft sleeve respectively used to connect the power input shaft and the power output shaft. The end of the left shaft sleeve is provided with drum-shaped teeth, and the coupling sleeve sleeved on the periphery of the left shaft sleeve passes through its internal teeth It meshes with the drum teeth on the left sleeve. The end of the right sleeve is provided with a connecting flange. The connecting flange and the connecting sleeve are connected and fixed by through bolts. A brake disc is clamped and fixed on the connecting flange and Between the connection sleeves.

WGP type drum gear type with brake discCouplingThe structure is simple and easy to install. The brake disc is rigidly connected to the right bushing. The braking load and vibration during braking are borne by the right bushing, so it will not damage the meshing performance of the drum teeth. At the same time, the brake disc itself The stability is also greatly improved, ensuring the reliability of operation.Gear coupling is composed of internal gear ring with the same number of teeth and flange half coupling with external teeth.

The external teeth are divided into straight teeth and drum teeth. The so-called drum teeth means that the external teeth are made into a spherical surface. The spherical surface is on the gear axis. The tooth side clearance is larger than that of ordinary gears. Drum gear couplings are allowed. Larger angular displacement (compared to straight tooth coupling) can improve the contact conditions of the teeth, increase the torque transmission capacity, and prolong the service life.The contact state along the tooth width when there is angular displacement.

-

Drum gear couplings are rigid-flexible couplings, with radial, axial and angular axis deviation compensation...

-

When the NGCL type drum gear coupling with brake wheel is working, the two shafts produce relative angular displacement, and the internal and external teeth are...

-

GICL type-drum gear coupling (JB/T 8845.3-2001) is a rigid-flexible coupling, gear coupling...

-

TGL type nylon inner gear ring drum gear coupling is the national standard model, another nylon inner gear produced by our factory...