- ※ Gear coupling

- ※ Diaphragm coupling

- ※ Plum blossom coupling

- ※ Star flexible coupling

- ※ Elastic pin coupling

- ※ Elastic pin gear coupling

- ※ Elastic sleeve pin coupling

- ※ Slider coupling

- ※ Rigid coupling

- ※ Sprocket chain coupling

- ※ Tyre coupling

- ※ Serpentine spring coupling

- ※ Universal coupling

- ※ Bracket series

- ※ Stirrer series

- ■ There are tips for surveying and mapping to make couplings...

- ■ Explain the movement of the diaphragm coupling...

- ■ Crusher coupling and pump coupling...

- ■ XINLAN manufacturers explain the coupling...

- ■ Durable gear coupling 38 Luo...

- ■ GSL type product XINLAN mechanical gear...

- ■ Improve the ranking of the coupling website...

- ■ Couplings with bolts XINLAN...

Open up and innovate, customer first

- ■ At the end of 2020, steel and freight are...

- ■ Find the coupling manufacturer to report...

- ■ XINLAN Machinery will chat with you about snakes...

- ■ Hundred sets of plum blossom 4 type coupling...

- ■ LZ type elastic coupling 2016...

- ■ 45# Steel Coupling/40 Luo Steel...

- ■ The nationwide increase in freight rates directly affects...

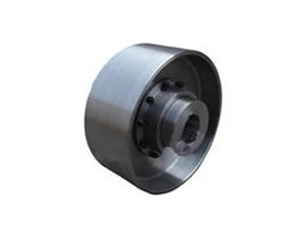

Drum shapeGear couplingRigid and flexibleCoupling, It has the ability to compensate for axis deviation in radial, axial and angular directions. Compared with CL type spur gear couplings, drum gear couplings have compact structure, small gyration radius, large carrying capacity and high transmission efficiency. , Low noise and long maintenance cycle.

Drum gear couplingFeatures (compared to straight gear couplings with the following features)

1. Strong carrying capacity.Under the same outer diameter of the inner gear sleeve and the large outer diameter of the coupling, the carrying capacity of the drum gear coupling is on average 15-20 higher than that of the straight gear coupling;

2. Large amount of angular displacement compensation.When the radial displacement is equal to zero, the allowable angular displacement of the spur gear coupling is 1º, while the allowable angular displacement of the drum gear coupling is 1º30”, which is increased by 50, at the same modulus, number of teeth, Under the tooth width, the allowable angular displacement of the drum gear is larger than that of the straight tooth;

3. The drum-shaped tooth surface improves the contact conditions of the inner and outer teeth, avoids the disadvantages of squeezing the edge of the straight tooth and stress concentration under the condition of angular displacement, and at the same time improves the friction and wear of the tooth surface, and reduces the noise. , Long maintenance period;

4. The tooth end of the outer gear sleeve is in the shape of a horn, which makes the assembly and disassembly of the inner and outer teeth very convenient.

5. The transmission efficiency is as high as 99.7.Based on the characteristics of the warp, at present, drum-shaped teeth have generally been substituted for straight-tooth couplings at home and abroad.

The drum gear couplings produced by our company have complete varieties and specifications, and meet the corresponding standards.Drum-shaped gear couplings are rigid, flexible, and inelastic, so they are not suitable for machinery that requires damping, buffering, and two-axis alignment.

-

Type GⅡCL—Drum-shaped gear coupling because the angular compensation of the drum-shaped gear coupling is greater than that of the straight-tooth coupling....

-

GICL type-drum gear coupling (JB/T 8845.3-2001) is a rigid-flexible coupling, gear coupling...

-

GⅡCLZ type—drum-shaped gear coupling is a half-coupling made of an inner gear ring with the same number of teeth and a flanged half-coupling with outer teeth...

-

When the NGCL type drum gear coupling with brake wheel is working, the two shafts produce relative angular displacement, and the internal and external teeth are...