- ※ Gear coupling

- ※ Diaphragm coupling

- ※ Plum blossom coupling

- ※ Star flexible coupling

- ※ Elastic pin coupling

- ※ Elastic pin gear coupling

- ※ Elastic sleeve pin coupling

- ※ Slider coupling

- ※ Rigid coupling

- ※ Sprocket chain coupling

- ※ Tyre coupling

- ※ Serpentine spring coupling

- ※ Universal coupling

- ※ Bracket series

- ※ Stirrer series

- ■ There are tips for surveying and mapping to make couplings...

- ■ Explain the movement of the diaphragm coupling...

- ■ Crusher coupling and pump coupling...

- ■ XINLAN manufacturers explain the coupling...

- ■ Durable gear coupling 38 Luo...

- ■ GSL type product XINLAN mechanical gear...

- ■ Improve the ranking of the coupling website...

- ■ Couplings with bolts XINLAN...

Open up and innovate, customer first

- ■ At the end of 2020, steel and freight are...

- ■ Find the coupling manufacturer to report...

- ■ XINLAN Machinery will chat with you about snakes...

- ■ Hundred sets of plum blossom 4 type coupling...

- ■ LZ type elastic coupling 2016...

- ■ 45# Steel Coupling/40 Luo Steel...

- ■ The nationwide increase in freight rates directly affects...

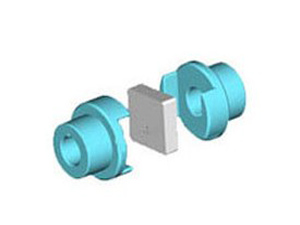

SL cross sliderCouplingThe Oldham slider coupling is also known as the metal slider coupling. The slider is in the shape of a circular ring and is made of steel or wear-resistant alloy. It is suitable for transmissions with low speed and large transmission torque.

The material of the Oldham coupling parts can be 45 steel, and the working surface needs to be heat treated to increase its hardness; Q275 steel can also be used when the requirements are lower, without heat treatment.In order to reduce friction and wear, oil should be injected from the oil hole of the intermediate plate for lubrication during use.The Oldham slider coupling is also known as the metal slider coupling. Its slider is in the shape of a circular ring and is made of steel or wear-resistant alloy. It is suitable for transmissions with low speed and large transmission torque.The cross slider coupling is composed of two half couplings with grooves on the end faces and a middle disc with convex teeth on both sides.Because the convex teeth can slide in the groove, the relative displacement between the two shafts during installation and operation can be compensated.

Because the semi-coupling and the intermediate disc form a moving pair and cannot rotate relative to each other, the angular velocity of the driving shaft and the driven shaft should be equal.However, when working with relative displacement between the two shafts, the middle disk will generate a large centrifugal force, resulting in dynamic load and wear.Therefore, pay attention to the working speed not greater than the specified value when selecting.This kind of coupling is generally used where the speed n<250r/min, the rigidity of the shaft is relatively large, and there is no severe impact.

SL cross slide coupling (Q/JL03-2001)

| specification | Nominal torque Tn(N·M) |

Permissible speed [n]r/min |

Diameter of shaft hole d |

D | D | L | H | S |

Moment of inertia (kg.m 2) |

weight (kg) |

| SL70 | 120 | 250 | 15 ~ 18 | 70 | 32 | 42 | 14 | 0.5 | 0.002 | 1.5 |

| SL90 | 250 | 250 | 20 ~ 30 | 90 | 45 | 52 | 14 | 0.008 | 2.6 | |

| SL100 | 500 | 250 | 36 ~ 40 | 100 | 60 | 70 | 19 | 0.026 | 5.5 | |

| SL130 | 800 | 250 | 45 ~ 50 | 130 | 80 | 90 | 19 | 0.07 | 10 | |

| SL150 | 1250 | 250 | 55 ~ 60 | 150 | 95 | 112 | 19 | 0.14 | 15.5 | |

| SL170 | 2000 | 250 | 65 ~ 70 | 170 | 105 | 125 | 24 | 0.25 | 22.4 | |

| SL190 | 3200 | 250 | 75 ~ 80 | 190 | 110 | 140 | 29 | 0.5 | 31.5 | |

| SL210 | 5000 | 250 | 85 ~ 90 | 210 | 130 | 160 | 33 | 1.0 | 0.9 | 45 |

| SL240 | 8000 | 250 | 95 ~ 100 | 240 | 140 | 180 | 33 | 1.6 | 59.5 | |

| SL260 | 9000 | 250 | 100 ~ 110 | 260 | 160 | 190 | 33 | 2 | 76 | |

| SL280 | 10000 | 100 | 110 ~ 120 | 280 | 170 | 200 | 33 | 3 | 94.3 | |

| SL300 | 13000 | 100 | 120 ~ 130 | 300 | 180 | 210 | 43 | 4.3 | 111 | |

| SL320 | 16000 | 100 | 130 ~ 140 | 320 | 190 | 220 | 43 | 5.7 | 129 | |

| SL340 | 20000 | 100 | 150 | 340 | 210 | 250 | 48 | 8.4 | 162 | |

| SL360 | 32500 | 100 | 160 | 360 | 240 | 280 | 48 | 19.2 | 258 | |

| SL400 | 38700 | 80 | 170 | 400 | 260 | 300 | 48 | 26.1 | 305 | |

| SL460 | 63000 | 70 | 200 | 460 | 300 | 350 | 58 | 62.9 | 560 |

-

The structure of WH type-slider coupling is similar to cross slider coupling, but the difference lies in the middle cross slider....